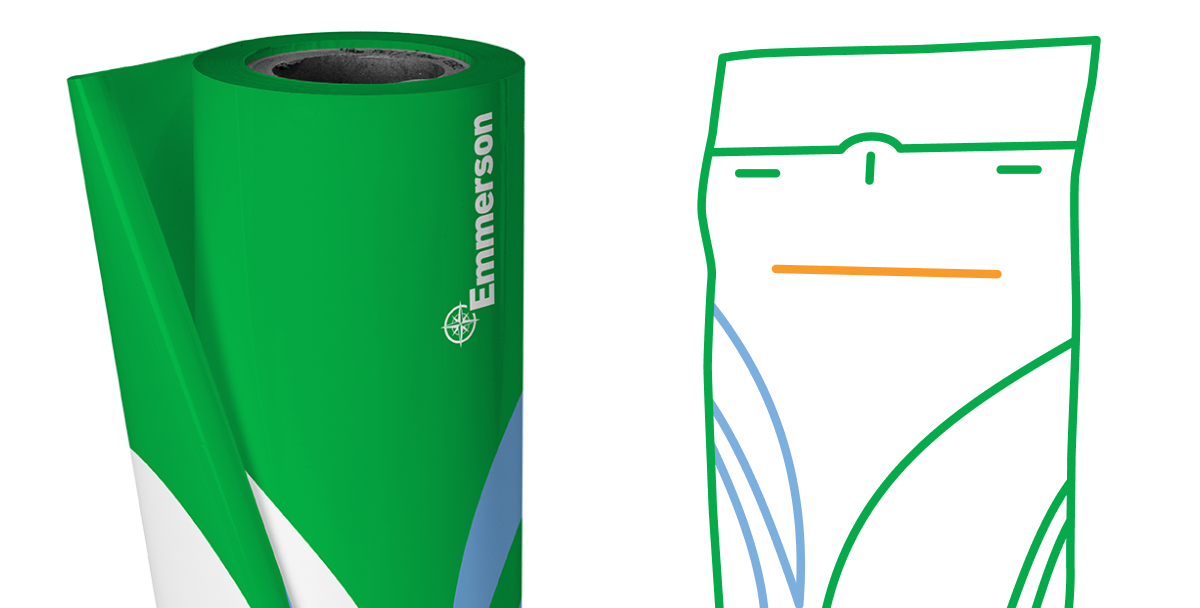

Add resealable closures without extra equipment.

Incorporate easy-to-use, resealable closures into your packaging. Inno-Lok® is conveniently pre-applied right onto your rollstock.

On-time guarantee

Project coordination

Affordable sustainability

Eye-catching graphics

Convenient resealable functionality that meets your needs.

- Front Panel Press-to-Close (PTC)

Front Panel Press-to-Close (PTC)

Get in TouchGive consumers convenient access to products with a recloseable feature at the front of your pouch. Front panel closures create small openings but can be easily incorporated into your production process.

- Bag Top Press-to-Close (PTC)

Bag Top Press-to-Close (PTC)

Get in TouchCustomers appreciate roomier, resealable openings at the top of the bag. Bag top closures give your packaging the convenience consumers love in a format that works with your vertical packing lines.

- 360 Sensory Press-to-Close (PTC)

360 Sensory Press-to-Close (PTC)

Get in TouchLooking to maximize space for consumers to dig in? Self-mating 360 closures allow for a full-width bag opening (and reclosure) after forming. The high-touch sensory closure, containing micro splits, mimics the feeling of hook-to-hook, giving your brand a more premium feel.

Improve packing speeds with specialized venting.

Air Slits

Air slits are an incredibly cost-effective way to perforate your packaging. Evacuate air from your packaging quickly and affordably while keeping your packing lines running at speed.

Wicket Punch Perfs

These economical perforations for polybags allow for rapid air evacuation during packing. No matter your polybag project, we’ll ensure the right size, shape and style of punch.

Micro-perfs

Concealed in your bag’s gussets, micro-perfs help release air from your packaging in a cost-effective and reliable way.

Needle Perfs

Like air slits, needle perfs evacuate air from your packaging but with smaller, less visible punctures. These smaller vents may be preferred if you’re looking to package finely ground products like herbs and spices.

Specialty Perfs

Some products like liquids may require specialty perfs. We use innovative technology like lasers to create custom ventilation points.

PetVent™

PetVent™ protects products at high risk for infestation. Avoid costly contamination with patented vented patches that keep freshness in, and insects out.

Frequently asked questions

- What locations does Emmerson Packaging service?

We service all of Canada and the United States. We have warehouses strategically located throughout to ensure that from coast to coast, your product is always close.

- Is Emmerson Packaging food grade?

Yes. All our packaging is FDA-approved, and our facilities are SQF Edition 8: Level 2 certified. You can access a copy of our most up to date SQF certifications here: Insert link to where this will live on the website.

- What is your minimum order quantity?

- Inno-Lok – 25,000 PC per SKU

As we are strategically set up to manufacture large-scale orders, most rollstock and Inno-Lok programs should be about 10 million annual impressions. If you’re not sure about whether you meet our minimum order requirements our team of experts is more than happy to review the details of your packaging programs.

- What are your standard lead times?

Lead times are based on where the product is being shipped to, but typically on repeat orders, standard have-ready lead times are 6 weeks for surface-printed Inno-Lok and 7 weeks for laminated inno-lok.

- What is your on-time delivery rate?

We boast a 98+% on-time delivery rate. We’re so confident in our ability to deliver your project on time, we offer a rock-solid New Product Launch Guarantee. If you miss a launch date and it’s our fault, we’ll pay a penalty fee! Learn more about our On-Time Guarantee today: On-Time Guarantee | Emmerson Packaging

- Do you make your own film?

Yes, we make our own polyethylene films. You can choose from clear, white, or add visual impact from our line of matte finish PE films. Our in-house Research and Development and Graphics teams can work with you to understand your goals and provide technical expertise, along with concept and design support to ensure that your goals are met. Complete our contact us form to coordinate a meeting today!

- Do you make your own plates?

Yes, we make our own plates in-house using an ESKO HD workflow

- Do you do HD printing?

Yes, our HD printing provides 4000 DPI resolution (in comparison to traditional 2400 DPI). Our capabilities also offer up to 175 LPI for superior ink lay down and color control, in comparison to traditional pre-press technologies.

- Do you do digital printing?

Emmerson Packaging does not currently offer digital printing. As a flexible packaging manufacturer that focuses on pet food, frozen food, and other markets of the like, we feel that flexographic printing is still the best solution for our customers, given their existing volumes and service requirements. We are actively exploring digital technologies and will deploy them when we feel they can meet our customers’ needs for quality and cost competitiveness.

- What are your in-house production capabilities?

Emmerson Packaging is a vertically-integrated manufacturing operation. We deliver consistent and high-quality services and products, with premium in-house production capabilities:

- HD Printing (4000 DPI resolution with 175 LPI for superior ink lay down and color control)

- High-speed flexographic presses with state-of-the-art robotic capabilities

- Print width ranges from 12” (minimum) to 65” (maximum)

- Print repeat ranges from 12 1/4” (minimum) to 49” (maximum)

- 10-colour maximum range plus combinations

- Surface or reverse sheeting or tubing

- Computer-controlled ink blending, dispensing, and matching

- What sets Emmerson Packaging apart from other manufacturers in terms of sustainability?

- We have been producing sustainable, recycle-ready stand-up pouches since 2019

- We offer a team of dedicated sustainable packaging R&D experts to ensure that you can meet your packaging goals.

- Beyond packaging innovations, our manufacturing facilities have long concentrated on sustainability initiatives, and we are SQF level 2 Certified.

- We were the first flexographic printer in North America to adopt ISO 14001 in order to guide the creation of our environmental management system.

- We were also the first Sustainable Green Printer (SGP) in Canada and the 6th in the US.

- Our products are peanut free – and we have complete product traceability!

- What do I need to know about PCR?

- PCR materials come from plastic products that have been recycled, collected, cleaned, reprocessed into PCR resin, and then made into something new. An example of products that are used to create PCR resin would be HDPE, milk jugs.

- PCR provides excellent packaging sustainability benefits, but they may impact print quality and/or film consistency. If the package is a lamination of two substrates, the PCR can be added to the substrate that is not being printed, and the print will not be compromised. However, if the specification is one substrate and not laminated, the PCR film may impact the graphics. One of the compromises of PCR is the presence of gels or unmelts which are areas that do not melt uniformly. They will show up as small hard spots. These gels will affect print as the ink will pool around the hard spots.

- Emmerson Packaging offers 15 – 25% content. Although 100% PCR packaging is available, the resin does not melt uniformly. As a result, there can be unmelts and gels present, which are small un-melted areas in the sealant film. To minimize this impact, we advise limiting the amount of PCR in the product.